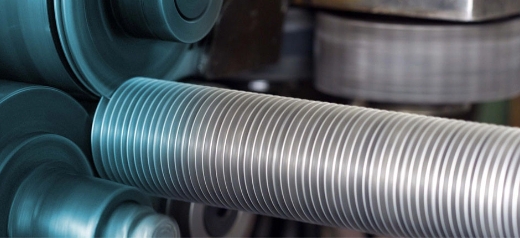

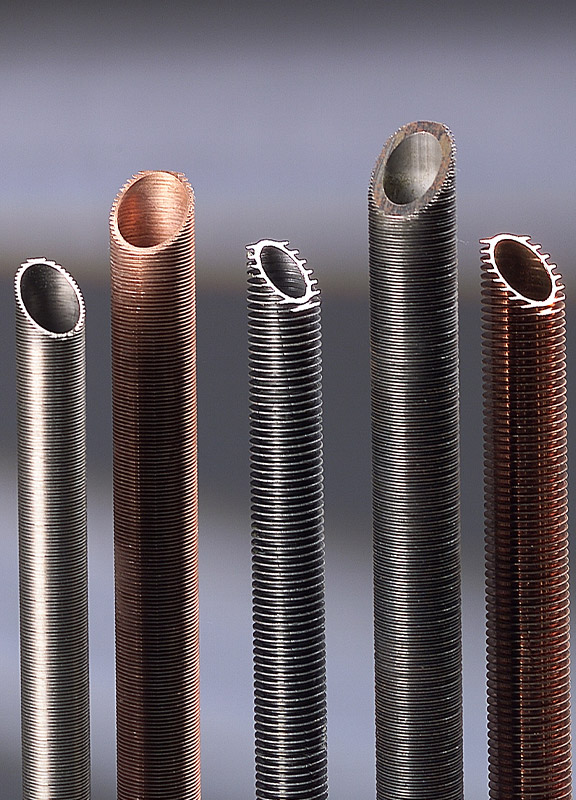

Pantani Group è l'insieme unito e coeso di aziende specializzate in curvatura, alettatura, corrugazione e taglio su misura di tubi, impiegati in ambito oil & gas, chimico & petrolchimico, geotermico, impianti ad energia rinnovabile, automotive e tanto altro.

Da oltre 30 anni, onoriamo i seguenti valori: specializzazione, puntualità, ascolto e cura del cliente, collaborazione, affidabilità e flessibilità.

scopri di più

scopri di più

Specializzazione

Mettiamo a vostra disposizione le nostre elevate e storiche competenze tecniche per realizzare lavorazioni su tubi di alta qualità, garantite nel tempo.

Mettiamo a vostra disposizione le nostre elevate e storiche competenze tecniche per realizzare lavorazioni su tubi di alta qualità, garantite nel tempo.

Puntualità

Il rispetto degli impegni presi è uno dei pilastri su cui si basano le nostre relazioni professionali.

Il rispetto degli impegni presi è uno dei pilastri su cui si basano le nostre relazioni professionali.

Ascolto e cura del cliente

Per noi, ascolto attivo ed empatia verso interlocutori interni & esterni sono elementi imprescindibili. Siamo presenti in quello che facciamo, dai piccoli gesti alle grandi soluzioni.

Per noi, ascolto attivo ed empatia verso interlocutori interni & esterni sono elementi imprescindibili. Siamo presenti in quello che facciamo, dai piccoli gesti alle grandi soluzioni.

Collaborazione

Siamo sempre presenti e al fianco delle nostre persone, clienti e fornitori. Crediamo nel valore di ogni individuo e nel potere del lavoro di squadra.

Siamo sempre presenti e al fianco delle nostre persone, clienti e fornitori. Crediamo nel valore di ogni individuo e nel potere del lavoro di squadra.

Affidabilità

Da oltre 30 anni siamo il punto di riferimento italiano per la curvatura, l'alettatura e la corrugazione di tubi. Ci prendiamo cura dei bisogni dei nostri clienti e dei benefici che desiderano.

Da oltre 30 anni siamo il punto di riferimento italiano per la curvatura, l'alettatura e la corrugazione di tubi. Ci prendiamo cura dei bisogni dei nostri clienti e dei benefici che desiderano.

Flessibilità

Siamo concavi e convessi: ascoltiamo le idee e le prospettive del cliente e sappiamo adattarci alla situazione sulla base delle sue esigenze.

Siamo concavi e convessi: ascoltiamo le idee e le prospettive del cliente e sappiamo adattarci alla situazione sulla base delle sue esigenze.

Perché scegliere noi?

Pantani Group si presenta sul mercato in modo autorevole, fornendo un ventaglio di soluzioni customizzate tramite un unico referente.

Forte della sua storica professionalità, expertise e dei valori che le aziende del Gruppo perseguono da oltre 30 anni, i nostri clienti tornano da noi periodicamente assegnandoci un rating di 9.5/10.

scopri di più

Forte della sua storica professionalità, expertise e dei valori che le aziende del Gruppo perseguono da oltre 30 anni, i nostri clienti tornano da noi periodicamente assegnandoci un rating di 9.5/10.

scopri di più

I nostri numeri

9.5/10

Grado di soddisfazione clienti

95%

Consegne puntuali

200000

Tubi curvati/anno

26589511

Numero tagli automotive/anno

Proattivamente al tuo fianco per:

Collaboriamo con acciaierie, costruttori di scambiatori di calore e studi d'ingegneria, per aiutarli a ottimizzare i processi produttivi, realizzando lavorazioni speciali su tubi per scambiatori di calore, permettendo loro di risparmiare tempo e denaro e garantendo tempi di consegna veloci e puntuali.

- Ottimizzare i processi produttivi

- Risparmiare tempo e denaro

- Garantire i tempi di consegna

News

18/10/2023

Progetto Language Toolkit - Il valore delle nuove generazioni

Siamo lieti di accogliere presso la nostra azienda una brillante studentessa universitaria della Scuola Interpreti e Traduttori (sede di Forlì), grazie al progetto Tool Kit. La sua collaborazione è fondamentale per migliorare la comunicazione aziendale del nostro gruppo.

Leggi di più

SCRIVICI PER INFORMAZIONI

scopri di più

scopri di più

scopri di più

scopri di più

scopri di più

scopri di più

scopri di più

scopri di più

scopri di più

scopri di più